Re-OPT is a Cutting Control station typically installed near the cutting table Numeric Control, specifically designed to manage breakage and to avoid last plate wastage.

Local breakage can be tagged directly using a touch screen monitor and automatically reoptimized on the next usable plate. Breakages can be declared by the cutting table operator but can be also integrated additional pieces, of the same material of current JOB, declared as broken to any GMC-Monitor tracking station.

Re-OPT check the pool list and, if needed, automatically add them to the current batch and reoptimize the reaming sequence.

Re-OPT is very useful when compliance with the production sequence is mandatory, usually for IG manufacturers and when combined with a Rack-Way sorting system and TV-Way monitoring software.

Functionality

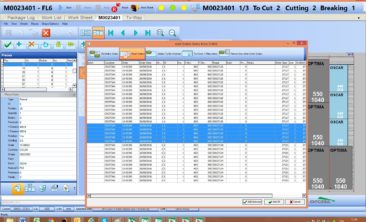

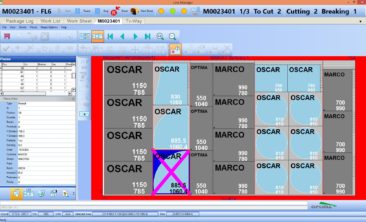

- Graphic Display of Cutting Diagram designed to work with Touch Screen System

- Constant material flow without cycle stops

- Minimization of waste and higher yield; considerable raw material savings

- Increased productivity of cutting lines, higher glass availability for the subsequent phases

- Significantly improved management of breakages and consequent reprocessing inside the production cycle

- Automatically Re-Optimization from that particular sheet in case of needs

- Manually edit specific sheeets

- Integration of Broken units from other Working Center

- Graphical display of glass defects (spots)

- Integration of Opty-Way Enterprise “Rush Orders” Integration with Crane Loader System

- Last Sheet Offcut Priority Optimization

- Connection to Opty-Way Enterprise SQL Database

- Communication with TsV-Way and Line Manager Monitoring Systems

- Printing the label “on the fly” of the executed plate

- Online control of Cutting Table