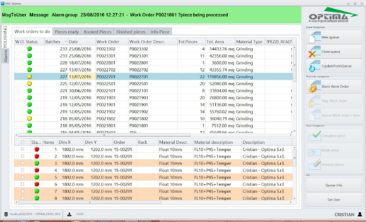

GMC-Monitor Tracking System is a module designed to retrieve current production status relative to prepared Batches or traceability information. GMC-Way can set each single unit and information recorded on the centralized Opty- Way Enterprise database as “completed” so every user of the Opty-Way Enterprise Sales Module or Production Module can see the production status of each Order or Order Line in “Real Time”.

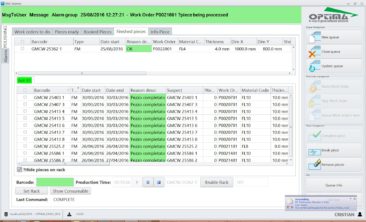

GMC-Monitor is capable to record the fabrication time of each unit, to record the machine equipment and assigned consumables and allow the assignment of the production rack of each unit. In case of breakage, the recuts pool is automatically created with no need for manual typing. Production statistics by Day, Week, Month can also be printed.

Functionality

- Visualization of Office Prepared Batches Fabrication List for IG line

- Visualization of B.O.M. and Working Process List in Assembling Sequence

- Data Collection of different scanners for each single Working Process

- Support of wired, wireless and fix-mounted scanners

- Allows Reading of Unit, Process or Batch ID from a Label or other Paper Lists

- Graphic visualization of Orders Data with Shapes

- One Shot Validation for Series Productions

- Store all information in one Tracking database table

- Person, Validation Time, Workstation, Access Point data also recorded

- Machine Equipment Storage for Traceability Recording

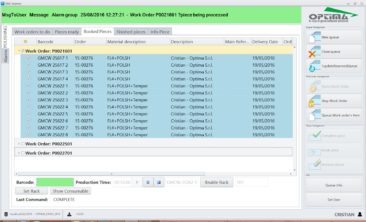

- Production History for Quality Management

- Online Feedback to Opty-Way Enterprise Database

- Checking, and if needed forced closing of previous Working Process

- Direct Label Reprinting

- Broken Unit Management with Recut Pool List for Re-Opt Online System

- Barcode Assignment of Rack Allocation of completed IG Unit

- Printing of Complete Rack allocation of selected Batch

- Printing of Packing Slips by Batch or Delivery Rack center

- Piece by piece check and validation on loading and unloading chain

- Can track and identify pieces that break inside the working center (get in but not get out)

- Complete trace of all events that occurred on the working center

- Accurate alarm management

- Supports manual actions over recorded data

- Directly connected to the Enterprise Database for data validation and broken piece management