Opty-Way Enterprise Standard is networks Microsoft SQL based application with a Batch based production module that can be used to manage any kind of processing operation such as tempering, laminating, screen printing, polishing, beveling and drilling. While mainly designed for production planning and production tracking, this application can be also integrated with thirds parties ERP systems.

Opty-Way Enterprise can automatically receive new orders coming from an ERP and provide feedback about production status to the ERP trough output file or via direct database connection in case of use of our “Connector” tool that allow, both systems, to share and synchronize all information.

Functionality

- Standard version include all features of the Opty-Way Enterprise Basic Program plus:

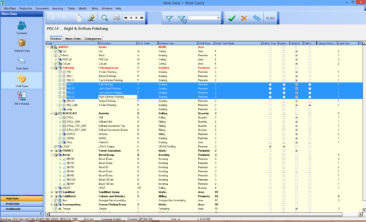

- Free Definition of Work Fabrication List

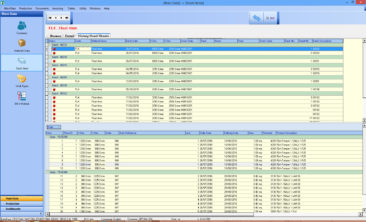

- Customizable management of Work Order creation for each machine or group of machines

- Free Definition of Working Center List

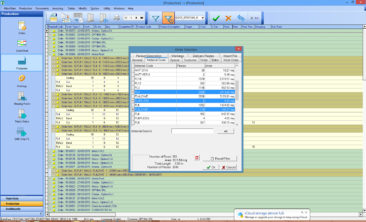

- Customizable B.O.M. (Bill of Materials)

- Custom SQL Filter Designer

- User Account Definition

- Custom Report Designer

- Customizable Company Logo for final product label and reports

- Production Statistic Predefined Reports List

- Delivery Rack Optional Management (Rack-Way Option)

- Order Header and Order Detail Multiple file format Attachments Management

- Shower Doors Doors-Way Module Included

- English Style Windows Bars-Way Module Included

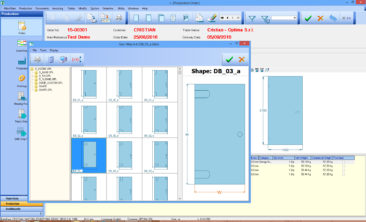

- CAD-Way module directly integrated into the Order Entry (CAD-Way Option)

- GMC-Way Tracking System Optional Support (GMC-Way Monitor Option)

- Order Status Management

- Optional Integration with Local ERP Solution (Connector or XGate Options)

- Production Planning Optional Module (Capacity Planner Module)

- Special management for Series Products

- Possibility to create Production tracking custom Dashboards (Reporting Services Dashboard Option)

- Daily mail can be scheduled to notify operators about daily productions (via Reporting Services)

- Automatic Mail Notification in case of breakages or of other relevant events that may occur in production (via Microsoft Reporting Services)