Main Interface of Opty-Way was re-designed in order to support “Big Icons” and be more user friendly to high resolution monitors. All icons have been also re-designed to be more clear and

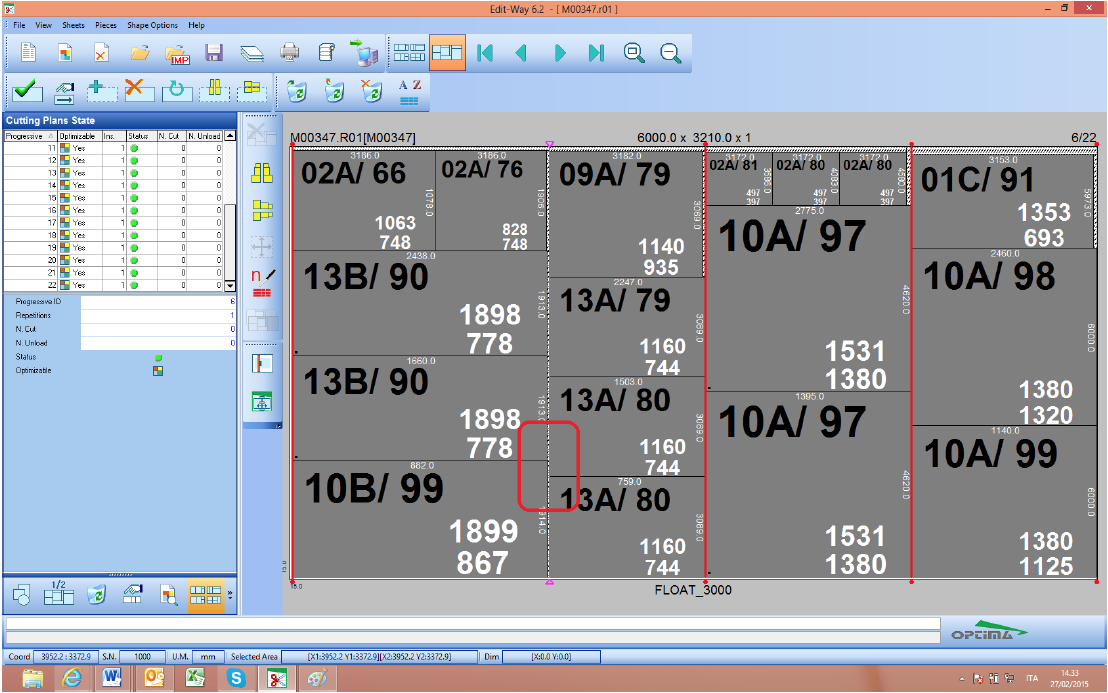

Shift Crosscut Management

An important new Optimization feature of Opty-Way program, is the Crosscut Shift Management. This new function, in several situations where Minimum Safety Distance being used, allows improving Optimization yield trough a shift of a Crosscut that’s create a space equal to the minimum distance required.

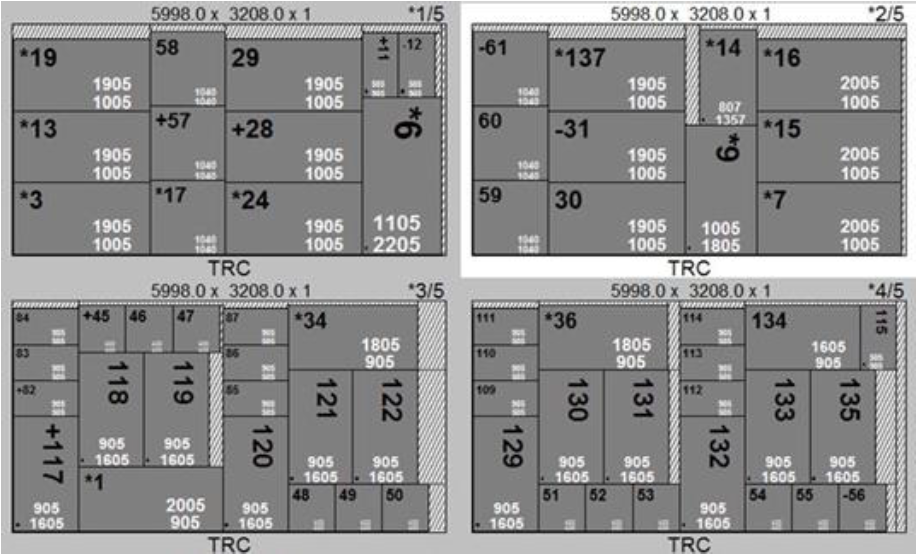

Sorting of Optimized Pieces

We are now able to “reorder” the cuts of each plate in order to simplify breakout operations. This rearrangement of the cuts consists first of all in a reorganization of the X crosscuts, in which are placed before the “taller” crosscuts (Y dimension) and then to descend all the others, keeping also neighbors the crosscuts composed by the same pieces. The second reordering consists in a “Pyramidal” sort type which arrange within each crosscut the pieces ordered, from bottom to top, from the wider to the narrower.

In this way it will be possible to switch from an optimization like this:

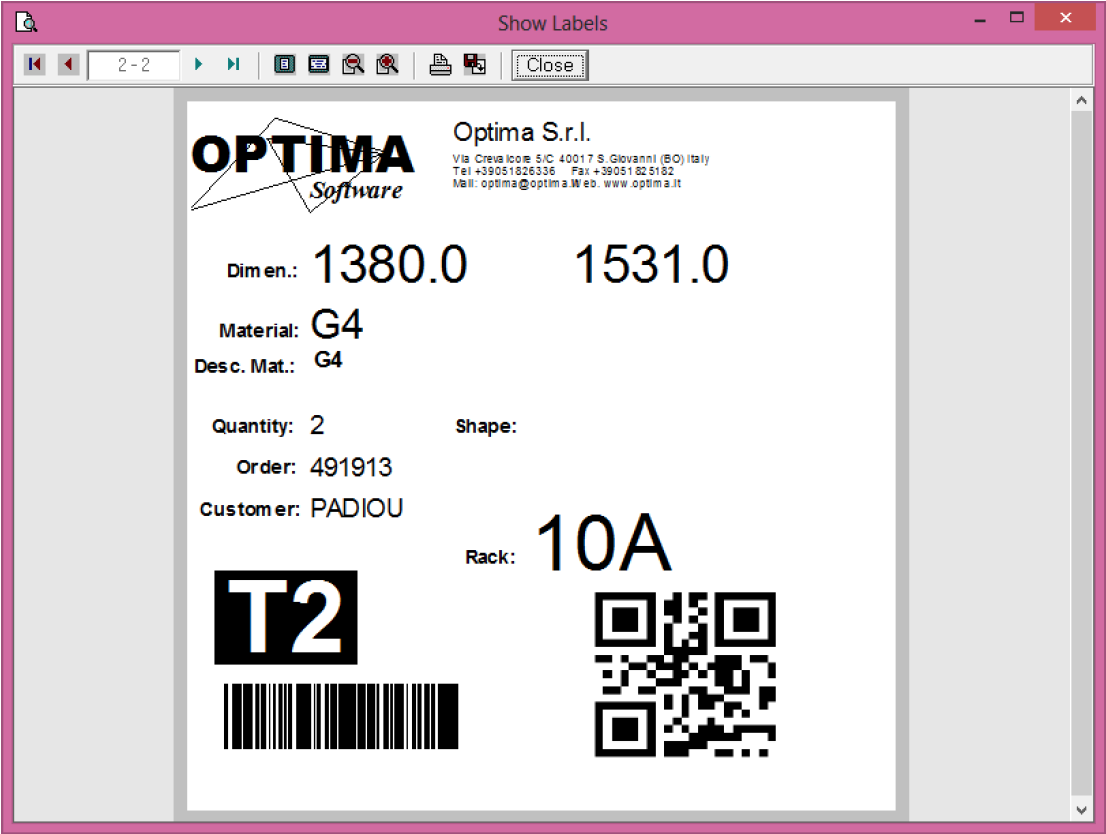

Label-Way

Now is possible to print labels from a wished cut plan inside the optimization to another, in the example is set up to print from the cut plan N°3 to cut plan N°4 and Holding the key “shift” and clicking onto the wished piece is possible to print the related labels only of the selected items.

We also added the possibility to print the QRCode, actually supported by several app of mobile devices to link a WEB page.